Page 160 - Tata_Chemicals_yearly-reports-2021-22

P. 160

Integrated Annual Report 2021-22

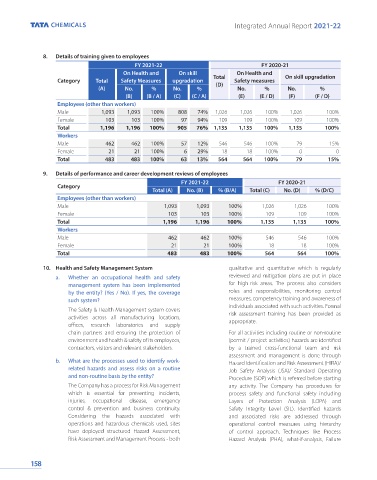

8. Details of training given to employees

FY 2021-22 FY 2020-21

On Health and On skill On Health and

Category Total Safety Measures upgradation Total Safety measures On skill upgradation

(A) No. % No. % (D) No. % No. %

(B) (B / A) (C) (C / A) (E) (E / D) (F) (F / D)

Employees (other than workers)

Male 1,093 1,093 100% 808 74% 1,026 1,026 100% 1,026 100%

Female 103 103 100% 97 94% 109 109 100% 109 100%

Total 1,196 1,196 100% 905 76% 1,135 1,135 100% 1,135 100%

Workers

Male 462 462 100% 57 12% 546 546 100% 79 15%

Female 21 21 100% 6 29% 18 18 100% 0 0

Total 483 483 100% 63 13% 564 564 100% 79 15%

9. Details of performance and career development reviews of employees

FY 2021-22 FY 2020-21

Category

Total (A) No. (B) % (B/A) Total (C) No. (D) % (D/C)

Employees (other than workers)

Male 1,093 1,093 100% 1,026 1,026 100%

Female 103 103 100% 109 109 100%

Total 1,196 1,196 100% 1,135 1,135 100%

Workers

Male 462 462 100% 546 546 100%

Female 21 21 100% 18 18 100%

Total 483 483 100% 564 564 100%

10. Health and Safety Management System qualitative and quantitative which is regularly

a. Whether an occupational health and safety reviewed and mitigation plans are put in place

management system has been implemented for high-risk areas. The process also considers

by the entity? (Yes / No). If yes, the coverage roles and responsibilities, monitoring control

such system? measures, competency training and awareness of

individuals associated with such activities. Formal

The Safety & Health Management system covers

activities across all manufacturing locations, risk assessment training has been provided as

offices, research laboratories and supply appropriate.

chain partners and ensuring the protection of For all activities including routine or non-routine

environment and health & safety of its employees, (permit / project activities) hazards are identified

contractors, visitors and relevant stakeholders. by a trained cross-functional team and risk

assessment and management is done through

b. What are the processes used to identify work- Hazard Identification and Risk Assessment (HIRA)/

related hazards and assess risks on a routine Job Safety Analysis (JSA)/ Standard Operating

and non-routine basis by the entity? Procedure (SOP) which is referred before starting

The Company has a process for Risk Management any activity. The Company has procedures for

which is essential for preventing incidents, process safety and functional safety including

injuries, occupational disease, emergency Layers of Protection Analysis (LOPA) and

control & prevention and business continuity. Safety Integrity Level (SIL). Identified hazards

Considering the hazards associated with and associated risks are addressed through

operations and hazardous chemicals used, sites operational control measures using hierarchy

have deployed structured Hazard Assessment, of control approach. Techniques like Process

Risk Assessment and Management Process - both Hazard Analysis (PHA), what-if-analysis, Failure

158