Page 170 - Tata_Chemicals_yearly-reports-2021-22

P. 170

Integrated Annual Report 2021-22

Biomass co-firing trails have been conducted successfully and currently running as well. The new plant at Mambattu is based on

renewable source of energy since inception where 80% of energy is from renewable sources like solar and biomass.

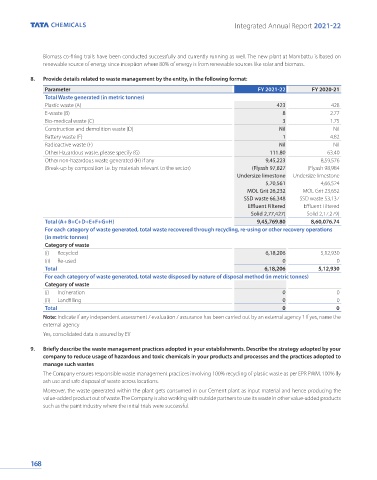

8. Provide details related to waste management by the entity, in the following format:

Parameter FY 2021-22 FY 2020-21

Total Waste generated (in metric tonnes)

Plastic waste (A) 423 428

E-waste (B) 8 2.77

Bio-medical waste (C) 3 1.75

Construction and demolition waste (D) Nil Nil

Battery waste (E) 1 4.82

Radioactive waste (F) Nil Nil

Other Hazardous waste, please specify (G) 111.80 63.40

Other non-hazardous waste generated (H) if any 9,45,223 8,59,576

(Break-up by composition i.e. by materials relevant to the sector) (Flyash 97,827 (Flyash 98,984

Undersize limestone Undersize limestone

5,70,561 4,66,524

MOL Grit 26,232 MOL Grit 23,652

SSD waste 66,348 SSD waste 53,137

Effluent Filtered Effluent Filtered

Solid 2,77,427) Solid 2,17,279)

Total (A+ B+C+D+E+F+G+H) 9,45,769.80 8,60,076.74

For each category of waste generated, total waste recovered through recycling, re-using or other recovery operations

(in metric tonnes)

Category of waste

(i) Recycled 6,18,206 5,12,930

(ii) Re-used 0 0

Total 6,18,206 5,12,930

For each category of waste generated, total waste disposed by nature of disposal method (in metric tonnes)

Category of waste

(i) Incineration 0 0

(ii) Landfilling 0 0

Total 0 0

Note: Indicate if any independent assessment / evaluation / assurance has been carried out by an external agency ? If yes, name the

external agency

Yes, consolidated data is assured by EY

9. Briefly describe the waste management practices adopted in your establishments. Describe the strategy adopted by your

company to reduce usage of hazardous and toxic chemicals in your products and processes and the practices adopted to

manage such wastes

The Company ensures responsible waste management practices involving 100% recycling of plastic waste as per EPR PWM, 100% fly

ash use and safe disposal of waste across locations.

Moreover, the waste generated within the plant gets consumed in our Cement plant as input material and hence producing the

value-added product out of waste. The Company is also working with outside partners to use its waste in other value-added products

such as the paint industry where the initial trials were successful.

168