Page 47 - Tata_Chemicals_2018-2019

P. 47

Integrated Annual Report 2018-19

Intensifying Focus on Health & Safety

Safety is an important part of our value system. We are relentlessly improving

our world-class safety performance based on a strong foundation of leadership,

strengthened by our ‘Zero Harm’ target for people, assets and environment.

Health and safety management miss through root cause analysis and Key safety initiatives FY 2018-19

in implementing preventive actions. Integrated Report

At Tata Chemicals, health and safety Global

initiatives are a key agenda. Specially formed Employees identify unsafe conditions • Cross-site safety audits and offsite

committees work towards reinforcing safety and report them on an e-enabled portal • Implementation of Work Safe Online

standards. Our dedicated Board Committees – WSO, which is regularly tracked to across sites

on CSR, Safety and Sustainability periodically ensure risk control. We carry out internal • Dedicated third-party packaging centres

review organisational safety and drive / external audits, inspections, surprise • Daily safety rounds and communication

strategic direction. Besides, the Apex Safety checks and engage experts to identify of safety observations to management

Committees at sites and Office Safety lapses and improvement areas and

Committees at offices review health and ensure effective implementation of safety • CFTs for safety improvements

safety of the employees, safety aspects systems. Although we constantly strive to Mithapur

and implementation of new policies and improve safety in working conditions, we • Systematic implementation of Process

guidelines. faced two unfortunate fatal incidents in Safety & Risk Management

FY 2018-19. We implemented corrective • Sensitisation on softer safety aspects

Assessing and managing actions to prevent such recurrences and through ‘Suraksha Samvad’

safety risks also supported the family of the deceased

We are constantly working towards under the Suraksha Scheme, a financial Magadi

• Safety projects under LASER workshop

evolving and upgrading our safety assistance scheme. We are also targeting

processes through periodic reviews and implementation of IoT solutions in • Employee engagement drives for near

benchmark them towards the Zero Harm FY 2019-20. miss identification, reporting and closure Statutory Reports

goal. We identify top safety risks and TCE

their mitigation plans are reviewed by the Emergency and crisis • Integration of dynamic risk assessment

CSR, Safety and Sustainability Committee preparedness with work permits

and Risk Management Committee. Our operations encompass comprehensive • Layer of Protection Analysis and CDM

Considering our use of hazardous processes for emergency preparedness, (Construction Design and Management)

chemicals, we have implemented response and crisis management. We implementation

structured Risk Assessment and undertake proactive measures to identify • Introduced Golden Safety Rules

Management processes and mitigation possible emergency scenarios and

plans across high risk areas. We engage calculate risk quantum. This is to prevent TCNA

trained functional teams for identifying them with engineering controls and • Articulation of life critical policies

and managing hazards in routine and non- maintenance practices, supported by a • Hazard Identification Tours

routine activities. systematic inspection regime and also

We prepare annual plans for asset assists us in being prepared in responding Way forward

management, besides workplace and to emergencies in real-time situations. During FY 2019-20, we aim to focus on

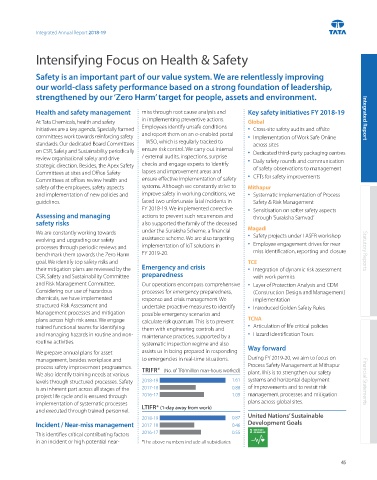

process safety improvement programmes. TRIFR* (No. of TRI/million man-hours worked) Process Safety Management at Mithapur

We also identify training needs at various plant. This is to strengthen our safety

levels through structured processes. Safety 2018-19 1.61 systems and horizontal deployment Financial Statements

is an inherent part across all stages of the 2017-18 0.88 of improvements and to revisit risk

project life cycle and is ensured through 2016-17 1.09 management processes and mitigation

implementation of systematic processes plans across global sites.

and executed through trained personnel. LTIFR* (1-day away from work)

2018-19 0.87 United Nations’ Sustainable

Incident / Near-miss management 2017-18 0.46 Development Goals

This identifies critical contributing factors 2016-17 0.55

in an incident or high potential near- *The above numbers include all subsidiaries

45