Page 139 - Tata Chemical Annual Report_2022-2023

P. 139

Integrated Annual Report 2022-23 01-83 84-192 193-365

Integrated Report Statutory Reports Financial Statements

Board's Report

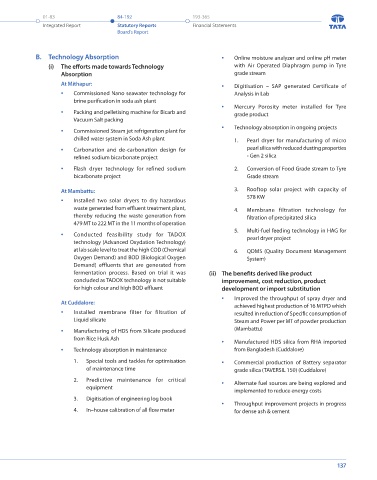

At Innovation Centre, Pune: (ii) The steps taken by the Company for utilising B. Technology Absorption • Online moisture analyzer and online pH meter

• Installed 100 KW rooftop solar power panels. alternate sources of energy: (i) The efforts made towards Technology with Air Operated Diaphragm pump in Tyre

Currently, the energy production stands at 450 • Continuous usage of groundnut shell (Biofuel) Absorption grade stream

Kwh/day and contributes to 20% of the total briquette at 20% mixed feed ratio in boiler At Mithapur:

energy consumption and Coal Fired Hot Air Generator at Cuddalore • Digitisation – SAP generated Certificate of

(CFHAG) • Commissioned Nano seawater technology for Analysis in Lab

• This installation correlates to 3,000 tonnes of brine purification in soda ash plant

carbon emission abatement which could benefit • Biomass fuel has been started in CFBC Boilers • Mercury Porosity meter installed for Tyre

around 5,000 trees planted per annum of Mithapur • Packing and pelletising machine for Bicarb and grade product

• Shredded plastic, spent resin & oil have been Vacuum Salt packing

• Having begun in January 2022, during the year, • Technology absorption in ongoing projects

103 tonnes of CO reduction is achieved through used in Cement plant of Mithapur • Commissioned Steam jet refrigeration plant for

2

solar system • Roof Top solar at Cuddalore has gone in to chilled water system in Soda Ash plant 1. Pearl dryer for manufacturing of micro

execution stage • Carbonation and de-carbonation design for pearl silica with reduced dusting properties

• 2 MW solar power plant for Mithapur township refined sodium bicarbonate project - Gen 2 silica

is being executed

• Flash dryer technology for refined sodium 2. Conversion of Food Grade stream to Tyre

(iii) Capital Investment on Energy Conservation Equipments: bicarbonate project Grade stream

` in crore

At Mambattu: 3. Rooftop solar project with capacity of

Sr. No. Project Description Capex Cost 578 KW

• Installed two solar dryers to dry hazardous

In the Soda Ash Plant at Mithapur:

waste generated from effluent treatment plant, 4. Membrane filtration technology for

1. WLDS Column replacement in Soda Ash Plant 3.84 thereby reducing the waste generation from filtration of precipitated silica

2. Replacement of IBIL and B&W Boiler Bed coil and Bed Super Heater coil 0.76 479 MT to 222 MT in the 11 months of operation

3. Upgradation of air heater of MUW-3 and 4 0.80 5. Multi-fuel feeding technology in HAG for

• Conducted feasibility study for TADOX

4. Electrical projects for energy saving 0.29 technology (Advanced Oxydation Technology) pearl dryer project

5. Pressure Filter Overhauling in cement plant 3.86 at lab scale level to treat the high COD (Chemical 6. QDMS (Quality Document Management

6. Major overhauling of TT-7 and TT-12 topper turbines 1.08 Oxygen Demand) and BOD (Biological Oxygen System)

In the Silica Plant at Cuddalore: Demand) effluents that are generated from

7. VFD for 22kW compressor and Melter recirculation 0.07 fermentation process. Based on trial it was (ii) The benefits derived like product

concluded as TADOX technology is not suitable improvement, cost reduction, product

8. Diesel Generator overhauling 0.35 for high colour and high BOD effluent development or import substitution

9. Harmonic Filter with D-tune filter 0.04 • Improved the throughput of spray dryer and

10. Boiler Steam trap heat recovery system 0.01 At Cuddalore:

achieved highest production of 16 MTPD which

11. Food Grade CFHAG skin tube replacement 0.65 • Installed membrane filter for filtration of resulted in reduction of Specific consumption of

12. Energy Management System 0.03 Liquid silicate Steam and Power per MT of powder production

In the Nutra Plant at Mambattu: • Manufacturing of HDS from Silicate produced (Mambattu)

13. Installation of condensate recovery system to recover the process steam condensate 0.24 from Rice Husk Ash • Manufactured HDS silica from RHA imported

14. Installation of two solar dryer systems to dry the hazardous waste generated from ETP 0.15 • Technology absorption in maintenance from Bangladesh (Cuddalore)

15. Installation of VFD for boiler 0.07

1. Special tools and tackles for optimisation • Commercial production of Battery separator

Total 12.24 of maintenance time grade silica (TAVERSIL 150) (Cuddalore)

2. Predictive maintenance for critical • Alternate fuel sources are being explored and

equipment

implemented to reduce energy costs

3. Digitisation of engineering log book

• Throughput improvement projects in progress

4. In–house calibration of all flow meter for dense ash & cement

136 137