Page 114 - Tata Chemical Annual Report_2022-2023

P. 114

Integrated Annual Report 2022-23 01-83 84-192 193-365

Integrated Report Statutory Reports Financial Statements

Business Responsibility &

Sustainability Report

(ii) Nature of operations 6. If the entity has undertaken any specific initiatives or used innovative technology or solutions to improve resource efficiency,

Manufacturing of Soda Ash & other basic chemistry products, Specialty chemicals, Agrochemicals and Nutrition or reduce impact due to emissions / effluent discharge / waste generated, please provide details of the same as well as

solutions outcome of such initiatives, as per the following format:

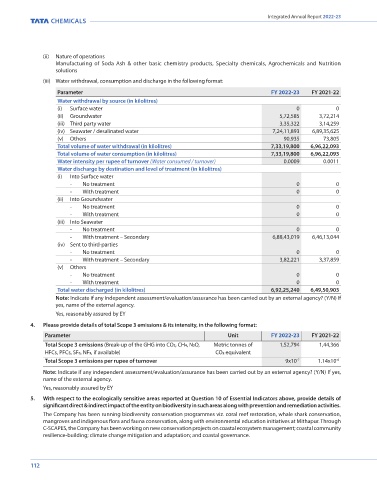

(iii) Water withdrawal, consumption and discharge in the following format:

Sr. Initiative undertaken Details of the initiative Outcome of the initiative

Parameter FY 2022-23 FY 2021-22 No. (Web-link, if any, may be provided along with

Water withdrawal by source (in kilolitres) summary)

(i) Surface water 0 0 1. Industrial scale carbon capture https://www.tatachemicalseurope.com/tata-chemicals- To make the world’s first carbon neutral

(ii) Groundwater 5,72,585 3,72,214 and utilisation (CCU) plant-UK europe-opens-uks-largest-carbon-capture-plant sodium bicarbonate. Reducing carbon

(iii) Third party water 3,35,322 3,14,259 by 40,000 tonnes

(iv) Seawater / desalinated water 7,24,11,893 6,89,35,625 2. Water Recycling Project i. Process condensate recovery and reusing it in process Reduction in water consumption

(v) Others 90,935 73,805 -Mambattu ii. Steam Condensate Recovery

Total volume of water withdrawal (in kilolitres) 7,33,19,800 6,96,22,093 3. Reduction of Hazardous waste Installation of Solar Dryer 50% reduction in hazardous

Total volume of water consumption (in kilolitres) 7,33,19,800 6,96,22,093 generation-Mambattu waste generation

Water intensity per rupee of turnover (Water consumed / turnover) 0.0009 0.0011

Water discharge by destination and level of treatment (in kilolitres) 4. Zero Land fill Project- Cuddalore Hazardous waste are now send to authorised agencies for Zero land fill of hazardous waste

reprocessing and coprocessing instead of Landfill

(i) Into Surface water

- No treatment 0 0 5. Integrated waste management https://sustainability.tatachemicals.com/our-approach/our- Conservation of natural resources

- With treatment 0 0 Utilisation of fly ash, under sized progress/environmental-compliance/

limestone and effluent solids in

(ii) Into Groundwater Cement manufacturing-Mithapur

- No treatment 0 0

- With treatment 0 0 6. Transporting through container The conversion of road movement into container rake Reduction of carbon emission

(iii) Into Seawater rakes-Mithapur movement for Product shipment

- No treatment 0 0 7. Construction of water structures Construction of 152 small water structures like farm pond, 22.1 MCFT for water storage

- With treatment – Secondary 6,88,43,019 6,46,13,044 in Dwarka District farm bund & well recharge

(iv) Sent to third-parties

- No treatment 0 0 7. Does the entity have a business continuity and disaster management plan? Give details in 100 words / web link.

- With treatment – Secondary 3,82,221 3,37,859 Yes, onsite and offsite emergency preparedness plan is in place. Mithapur has completed the assessment for ISO 22301:2019.

(v) Others ISO 22301:2019 - BCMS implementation for Cuddalore, Mambattu and Corporate (Wadala, Bombay House and Gift city) is

- No treatment 0 0 almost complete.

- With treatment 0 0

Total water discharged (in kilolitres) 6,92,25,240 6,49,50,903 TCL has the primary data centre (DC) situated in Mumbai, and disaster recovery (DR) site situated in Bengaluru (Different seismic

Note: Indicate if any independent assessment/evaluation/assurance has been carried out by an external agency? (Y/N) If zone) which is managed by third party. DR setup is implemented for only SAP application as it is deemed critical for business

yes, name of the external agency. operations. Periodical DR drills are conducted.

Business Continuity Plans (BCP) are designed to help the Company to recover from a disruption in production activity. Specifically,

Yes, reasonably assured by EY

BCP provides guidance to ensure that the Manufacturing units can respond effectively to a disruption and restore production

4. Please provide details of total Scope 3 emissions & its intensity, in the following format: operations as quickly as possible.

Parameter Unit FY 2022-23 FY 2021-22 The objectives of BCP for Manufacturing plants are to identify various threats that can disrupt the business operations. Identify

Total Scope 3 emissions (Break-up of the GHG into CO2, CH4, N2O, Metric tonnes of 1,52,794 1,44,366 advanced arrangements and procedures that will enable the team to respond quickly to an emergency event and ensure

HFCs, PFCs, SF6, NF3, if available) CO2 equivalent continuous performance of critical business functions. Reduce employee injury or loss of life and minimise damage and losses.

Protect essential facilities, equipment, vital records, and other assets. Identify teams which would need to respond to a crisis

Total Scope 3 emissions per rupee of turnover 9x10 -7 1.14x10 -6

and describe specific responsibilities. Facilitate effective decision-making to ensure that agency operations are restored in a

Note: Indicate if any independent assessment/evaluation/assurance has been carried out by an external agency? (Y/N) If yes, timely manner. Identify alternative courses of action to minimise and/or mitigate the effects of the crisis and shorten the agency

name of the external agency. response time. Quantify the impact of any kind of event in terms of money, time, business and workforce. Recover quickly from an

Yes, reasonably assured by EY emergency event and resume to full-scale manufacturing of products in a timely manner. Maintain the quality of manufactured

goods and products and keep consistency prioritised, protecting our customer base and brand during an emergency event.

5. With respect to the ecologically sensitive areas reported at Question 10 of Essential Indicators above, provide details of

significant direct & indirect impact of the entity on biodiversity in such areas along with prevention and remediation activities. 8. Disclose any significant adverse impact to the environment, arising from the value chain of the entity. What mitigation or

adaptation measures have been taken by the entity in this regard.

The Company has been running biodiversity conservation programmes viz. coral reef restoration, whale shark conservation,

mangroves and indigenous flora and fauna conservation, along with environmental education initiatives at Mithapur. Through No significant impact

C-SCAPES, the Company has been working on new conservation projects on coastal ecosystem management; coastal community 9. Percentage of value chain partners (by value of business done with such partners) that were assessed for environmental impacts.

resilience-building; climate change mitigation and adaptation; and coastal governance. 63%

112 113