Page 113 - Tata Chemical Annual Report_2022-2023

P. 113

Integrated Annual Report 2022-23 01-83 84-192 193-365

Integrated Report Statutory Reports Financial Statements

Business Responsibility &

Sustainability Report

9. Briefly describe the waste management practices adopted in your establishments. Describe the strategy adopted by your Leadership Indicators

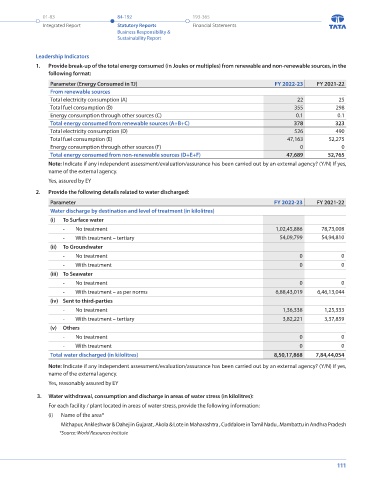

company to reduce usage of hazardous and toxic chemicals in your products and processes and the practices adopted to 1. Provide break-up of the total energy consumed (in Joules or multiples) from renewable and non-renewable sources, in the

manage such wastes. following format:

The Company ensures responsible waste management practices involving recycling of plastic waste as per applicable EPR PWM, Parameter (Energy Consumed in TJ) FY 2022-23 FY 2021-22

recycling and reuse of waste oil in the CRS dryer, fly ash utilisation, removal and replacement of asbestos with iron sheets and From renewable sources

ensuring safe disposal through Authorised licensed vendors and safe disposal of waste across locations. Moreover, the waste Total electricity consumption (A) 22 25

generated within the plant gets consumed in our Cement plant as input material and hence producing the value-added product Total fuel consumption (B) 355 298

out of waste. Energy consumption through other sources (C) 0.1 0.1

Total energy consumed from renewable sources (A+B+C) 378 323

Spent acids are sent for recycling to authorised end user to make useful products. Aqueous/Organic waste is sent to the authorised Total electricity consumption (D) 526 490

common incinerator system. As per our policy, we have discontinued production of the highly toxic red triangle products as per Total fuel consumption (E) 47,163 52,275

the Insecticides Act. Thus, the product portfolio and waste generated remains relatively less toxic.

Energy consumption through other sources (F) 0 0

Total energy consumed from non-renewable sources (D+E+F) 47,689 52,765

Non-toxic wastewater from process, canteen, amenities, cooling towers, boiler blow-down, etc. is treated in Effluent Treatment

Plant (ETP). ETP is equipped with primary, secondary, tertiary treatment followed by an Reverse Osmosis (RO) system. Tertiary Note: Indicate if any independent assessment/evaluation/assurance has been carried out by an external agency? (Y/N) If yes,

treated effluent is either recycled through RO or discharged to the common effluent system. The Aqueous effluent generated name of the external agency.

from processes having low COD and high TDS is fed to the Multiple Effect Evaporator and condensate of the evaporator is Yes, assured by EY

sent for treatment in the Effluent treatment plant or recycled/reused. The sludge generated from the evaporator/ETP is sent 2. Provide the following details related to water discharged:

to an authorised secured landfill site. High calorific and high TDS value hazardous waste is sent for processing to authorised

co-processors and further to cement industry. Parameter FY 2022-23 FY 2021-22

Water discharge by destination and level of treatment (in kilolitres)

10. If the entity has operations/offices in/around ecologically sensitive areas (such as national parks, wildlife sanctuaries, (i) To Surface water

biosphere reserves, wetlands, biodiversity hotspots, forests, coastal regulation zones etc.) where environmental approvals - No treatment 1,02,45,886 78,73,008

/ clearances are required, please specify details in the following format:

- With treatment – tertiary 54,09,799 54,94,810

S. Location of Types of operation Whether the conditions of environmental approval / clearance are (ii) To Groundwater

No. operations / offices being complied with? (Y/N) If no, the reasons thereof and corrective - No treatment 0 0

action taken, if any. - With treatment 0 0

1. Mithapur Manufacturing Yes

(iii) To Seawater

11. Details of environmental impact assessments of projects undertaken by the entity based on applicable laws, in the current - No treatment 0 0

financial year: - With treatment – as per norms 6,88,43,019 6,46,13,044

(iv) Sent to third-parties

Name and brief details of EIA Notification Whether conducted Results Relevant web link

the project No. and Date by independent communicated - No treatment 1,36,338 1,25,333

external agency in public domain - With treatment – tertiary 3,82,221 3,37,859

(Yes / No) (Yes / No) (v) Others

Not Applicable - No treatment 0 0

- With treatment 0 0

12. Is the entity compliant with the applicable environmental law/ regulations/ guidelines in India; such as the Water (Prevention Total water discharged (in kilolitres) 8,50,17,868 7,84,44,054

and Control of Pollution) Act, Air (Prevention and Control of Pollution) Act, Environment Protection Act and rules thereunder Note: Indicate if any independent assessment/evaluation/assurance has been carried out by an external agency? (Y/N) If yes,

(Y/N). If not, provide details of all such non-compliances, in the following format:

name of the external agency.

S Specify the law / regulation Provide the details of Any fines / penalties / action taken Corrective action Yes, reasonably assured by EY

No. the non-compliance by regulatory agencies such as taken, if any 3. Water withdrawal, consumption and discharge in areas of water stress (in kilolitres):

Pollution Control Board or by courts

For each facility / plant located in areas of water stress, provide the following information:

Not Applicable

(i) Name of the area*

Mithapur, Ankleshwar & Dahej in Gujarat , Akola & Lote in Maharashtra , Cuddalore in Tamil Nadu , Mambattu in Andhra Pradesh

*Source: World Resources Institute

110 111