Page 96 - Tata_Chemicals_yearly-reports-2021-22

P. 96

Integrated Annual Report 2021-22

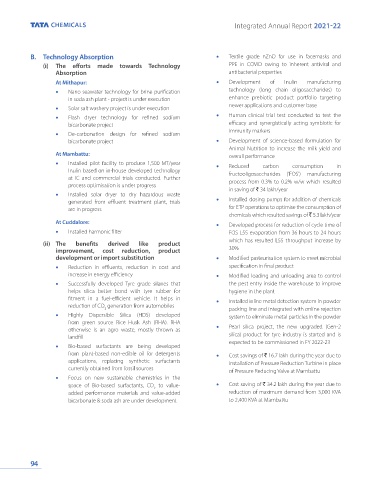

B. Technology Absorption • Textile grade nZnO for use in facemasks and

(i) The efforts made towards Technology PPE in COVID owing to inherent antiviral and

Absorption antibacterial properties

At Mithapur: • Development of Inulin manufacturing

• Nano seawater technology for brine purification technology (long chain oligosaccharides) to

in soda ash plant - project is under execution enhance prebiotic product portfolio targeting

newer applications and customer base

• Solar salt washery project is under execution

• Flash dryer technology for refined sodium • Human clinical trial test conducted to test the

bicarbonate project efficacy and synergistically acting symbiotic for

immunity markers

• De-carbonation design for refined sodium

bicarbonate project • Development of science-based formulation for

Animal Nutrition to increase the milk yield and

At Mambattu: overall performance

• Installed pilot facility to produce 1,500 MT/year • Reduced carbon consumption in

Inulin based on in-house developed technology fructooligosaccharides (‘FOS’) manufacturing

at IC and commercial trials conducted. Further

process optimisation is under progress process from 0.3% to 0.2% w/w which resulted

in saving of ` 34 lakh/year

• Installed solar dryer to dry hazardous waste

generated from effluent treatment plant, trials • Installed dosing pumps for addition of chemicals

are in progress for ETP operations to optimise the consumption of

chemicals which resulted savings of ` 5.3 lakh/year

At Cuddalore: • Developed process for reduction of cycle time of

• Installed harmonic filter FOS L55 evaporation from 36 hours to 24 hours

(ii) The benefits derived like product which has resulted L55 throughput increase by

improvement, cost reduction, product 30%

development or import substitution • Modified pasteurisation system to meet microbial

• Reduction in effluents, reduction in cost and specification in final product

increase in energy efficiency • Modified loading and unloading area to control

• Successfully developed Tyre grade silanes that the pest entry inside the warehouse to improve

helps silica better bond with tyre rubber for hygiene in the plant

fitment in a fuel-efficient vehicle. It helps in • Installed inline metal detection system in powder

reduction of CO generation from automobiles

2 packing line and integrated with online rejection

• Highly Dispersible Silica (HDS) developed system to eliminate metal particles in the powder

from green source Rice Husk Ash (RHA). RHA

otherwise is an agro waste, mostly thrown as • Pearl silica project, the new upgraded (Gen-2

landfill silica) product for tyre industry is started and is

expected to be commissioned in FY 2022-23

• Bio-based surfactants are being developed

from plant-based non-edible oil for detergents • Cost savings of ` 16.7 lakh during the year due to

applications, replacing synthetic surfactants installation of Pressure Reduction Turbine in place

currently obtained from fossil sources of Pressure Reducing Valve at Mambattu

• Focus on new sustainable chemistries in the

space of Bio-based surfactants, CO to value- • Cost saving of ` 34.2 lakh during the year due to

2

added performance materials and value-added reduction of maximum demand from 3,000 KVA

bicarbonate & soda ash are under development to 2,400 KVA at Mambattu

94