Page 95 - Tata_Chemicals_yearly-reports-2021-22

P. 95

01 INTEGRATED 73 STATUTORY 178 FINANCIAL

REPORTS

STATEMENTS

REPORT

Board’s Report

II. Harmonic filters installed power house and hot air • Jet cleaning system in filter press to reduce the water

generator (CFHAG) detune filters consumption

III. Auto power factor controller panel detune filter

At the Innovation Centre, Pune:

IV. 160 KVA uninterrupted power supply

• Installed 100 KW rooftop solar power panels. Currently,

• Ongoing projects include: the energy production stands at 450 Kwh/day and

I. CFHAG bio fuel trial completed and continuous contributes to 20% of the total energy consumption.

feeding will start after feeding system This installation correlates to 3,000 tonnes of carbon

upgradation

emission abatement which could benefit around 5,000

II. Solar project roof top is in the commercial trees planted per annum

ordering stage

• Having begun in January 2022, 31 tonnes of CO

III. Rainwater harvested water reused to garden as 2

well as in utilities reduction is achieved through electricity saving due

to planned shutdown (18.8 tonnes) and solar system

IV. Replacement of existing filter plates with new

designs to reduce the water consumption (12.2 tonnes)

V. SOP for filter press operator to reduce the wash (ii) The steps taken by the Company for utilising

water consumption alternate sources of energy:

VI. Water inlet from bottom and outlet from top • Consumed alternate fuels: shredded plastics, spent

changed on the filter press to reduce the water resin, spent oil, spent grease, TDI Tar at Mithapur

consumption

VII. Exploring the utilisation of sulfuric acid for which • Solar rooftop energy project is in final stage of

a detailed investigation is underway to obtain commercial discussion and is expected to be

high quality acid for our utilisation completed in FY 2022-23

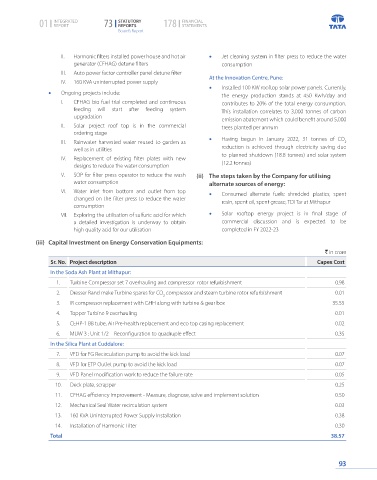

(iii) Capital Investment on Energy Conservation Equipments:

` in crore

Sr. No. Project description Capex Cost

In the Soda Ash Plant at Mithapur:

1. Turbine Compressor set 7 overhauling and compressor rotor refurbishment 0.98

2. Dresser Rand make Turbine spares for CO compressor and steam turbine rotor refurbishment 0.01

2

3. IR compressor replacement with GHH along with turbine & gear box 35.55

4. Topper Turbine 9 overhauling 0.01

5. CEHP-1 BB tube, Air Pre-health replacement and eco top casing replacement 0.02

6. MUW 3 : Unit 1/2 – Reconfiguration to quadruple effect 0.35

In the Silica Plant at Cuddalore:

7. VFD for FG Recirculation pump to avoid the kick load 0.07

8. VFD for ETP Outlet pump to avoid the kick load 0.07

9. VFD Panel modification work to reduce the failure rate 0.05

10. Deck plate, scrapper 0.25

11. CFHAG efficiency improvement - Measure, diagnose, solve and implement solution 0.50

12. Mechanical Seal Water recirculation system 0.03

13. 160 KVA Uninterrupted Power Supply Installation 0.38

14. Installation of Harmonic Filter 0.30

Total 38.57

93