Page 51 - Tata_Chemicals_yearly-reports-2020-2021

P. 51

Integrated Report Statutory Reports Financial Statements

Integrated Annual Report 2020-21 Addressing Environmental 60-146 147-300

Challenges for a Sustainable

World

emission management Initiated building one of UK’s largest,

India greenest energy from waste plants on

the Lostock site (schedule commissioning

Double effect evaporator in MUW3 plant is 2023) to neutralise flue gas emissions from

converted into quadruple effect evaporator Briskarb manufacturing with zero addition

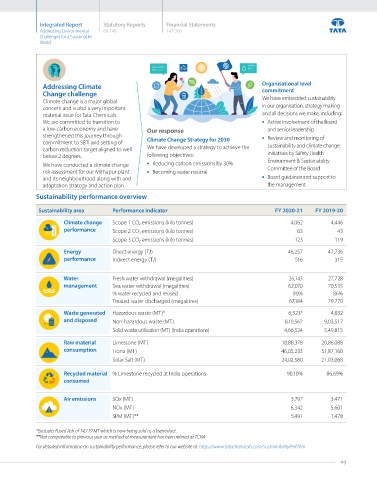

resulting into 26,257 TPA Coal saving to Scope 3 emissions Addressing Climate organisational level

equivalent to 47,641 TPA CO 2 emission Change challenge commitment

reduction Investigating in-house warehousing Climate change is a major global We have embedded sustainability

solutions (to be initiated in 2022) for large in our organisation, strategy making

UsA scale reduction of Scope 3 emission relating concern and is also a very important

Undertook multiple initiatives at C and D to offsite movements of products to material issue for Tata Chemicals. and all decisions we make, including:

Boilers: external warehouses We are committed to transition to Active involvement of the Board

Voluntarily reduced PM (particulate Kenya a low-carbon economy and have our response and senior leadership

matter) emission limits from 0.039 lb/ Focussed initiative to reduce dust emission strengthened this journey through Climate Change strategy for 2030 Review and monitoring of

MMBtu to 0.030 lb/MMBtu to create a UK commitment to SBTi and setting of We have developed a strategy to achieve the sustainability and climate change

bank of PM emission offsets for pending Commissioned state-of-the-art boiler at Kajidao by installing chutes and internal carbon reduction target aligned to well initiatives by Safety Health

dust meter to track dust levels

and future permitting plant at the British Salt plant, having ~94% below 2 degrees. following objectives:

Replaced CEMS for all regulated efficiency resulting in a 8,500 TPA reduction Commissioned CEMS (Continuous Emission We have conducted a climate change Reducing carbon emissions by 30% Environment & Sustainability

pollutants in CO 2 Monitoring System) project at ESP plant risk assessment for our Mithapur plant Becoming water neutral Committee of the Board

Exploring the elimination of coal by Commissioned Carbon Capture and The Automatic Weather Station (AWS) and its neighbourhood along with and Board guidance and support to

replacing it with efficient natural gas units Utilisation scheme for capturing food and provide daily Weather data adaptation strategy and action plan. the management

Installed Dry Sobert Injection system with pharmaceutical grade CO 2 for use in the Started programme to plant 22,000 trees sustainability performance overview

continuous SO 2 reductions Sodium Bicarbonate plant, contributing to within Magadi environs

Replaced six continuous opacity monitors a 40,000 TPA reduction in CO 2 emissions sustainability area Performance indicator FY 2020-21 FY 2019-20

(COMS) in the GR2 and GR3 calciners for all and enabling production of carbon neutral

regulated pollutants Sodium Bicarbonate Climate change Scope 1 CO 2 emissions (kilo tonnes) 4,062 4,446

performance Scope 2 CO 2 emissions (kilo tonnes) 63 43

Scope 3 CO 2 emissions (kilo tonnes) 123 119

Waste management UK energy Direct energy (TJ) 46,257 47,736

India Re-utilisation of brownfield site: Winnington performance Indirect energy (TJ) 516 315

Used plastic waste (~373 tonnes) as land scheme to return 5 km of prime

alternative fuel for Cement plant Cheshire river frontage to public access

Bulk transportation of products through use, other investment in public open space Water Fresh water withdrawal (megalitres) 26,143 27,728

and flood attenuation and bio-diversity

railway, bulkers and containers to eliminate management Sea water withdrawal (megalitres) 62,070 70,535

plastic packaging measures % water recycled and reused 90% 86%

Ensured 100% fly ash utilisation and 92.31% Kenya Treated water discharged (megalitres) 67,184 79,770

Disposed asbestos containing roof sheets as

of recycle of waste

per regulations

UsA Sold fused ash waste to a customer as input Waste generated Hazardous waste (MT)* 6,523* 4,832

Ongoing project to upgrade paste plant raw material resulting in waste recycle ratio and disposed Non-hazardous waste (MT) 8,10,562 9,03,517

improving to 99% Solid waste utilisation (MT) (India operations) 4,66,524 5,49,815

Raw material Limestone (MT) 18,88,378 20,86,088

Water conservation/management consumption patterns and lower the consumption

India water withdraw from the Green River Trona (MT) 46,05,233 51,87,160

TCSRD implemented water conservation UK Solar Salt (MT) 24,02,580 21,03,068

and water management work in 45 villages The British Salt Middlewich site reduced freshwater

of Okhamandal and Kalyanpur taluka consumption by harvesting rainwater for use within Recycled material % Limestone recycled at India operations 90.10% 86.69%

Supported construction of community and the plant consumed

individual water harvesting structures and Sites having large state-of-the-art recycle and

promotion of Micro Irrigation Systems - Drip reuse system (for raising, condensing and Air emissions SOx (MT) 3,797 3,471

and Sprinkler re-raising steam or using it in the Sodium

Water harvesting capacity added till date is Bicarbonate manufacturing process), NOx (MT) 6,342 5,601

441 MCFT minimising additional consumption SPM (MT)** 5,491 1,478

UsA Kenya

Installed flow meters throughout the Awareness creation on water conservation *Excludes Fused Ash of 14,119 MT which is now being sold as a byproduct.

**Not comparable to previous year as method of measurement has been refined at TCNA

water loop to better track water completed with water rationing

For detailed information on sustainability performance, please refer to our website at https://www.tatachemicals.com/SustainabilityPerf.htm

48 49