Page 48 - Tata_Chemicals_yearly-reports-2020-2021

P. 48

Integrated Report Statutory Reports Financial Statements

Integrated Annual Report 2020-21 Addressing Environmental 60-146 147-300

Challenges for a Sustainable

World

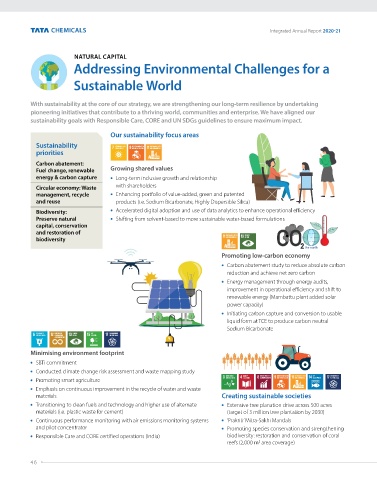

nATURAL CAPITAL our sustainability framework

Addressing environmental Challenges for a

sustainable World

With sustainability at the core of our strategy, we are strengthening our long-term resilience by undertaking Sustainability strategy Underpinned by our Oversight and E-enablement to digitally track

pioneering initiatives that contribute to a thriving world, communities and enterprise. We have aligned our and policies to guide corporate strategy: ultimate responsibility sustainability KPIs which is

sustainability goals with Responsible Care, CoRe and Un sDGs guidelines to ensure maximum impact. areas of intervention, Integrate undertaken by Safety, reviewed on an annual basis

support best practices sustainability across Health, Environment

our sustainability focus areas and drive encouraging business and Sustainability and

sustainability business change Maintain robust Risk Management

priorities systems and Committees. They

Carbon abatement: processes are updated on

Fuel change, renewable Growing shared values Focus on operational performance across

energy & carbon capture Long-term inclusive growth and relationship efficiencies and all internally defined

Circular economy: Waste with shareholders carbon abatement sustainability-related

material issues

management, recycle Enhancing portfolio of value-added, green and patented plans

and reuse products (i.e. Sodium Bicarbonate, Highly Dispersible Silica)

Biodiversity: Accelerated digital adoption and use of data analytics to enhance operational efficiency

Preserve natural Shifting from solvent-based to more sustainable water-based formulations Key sustainability initiatives undertaken in FY 2020-21 Managing waste sustainably

capital, conservation

and restoration of energy conservation UK

biodiversity Cement kiln is an environment-friendly place

India Founding member of the NetZero to dispose of waste where temperatures of

11,53,371 kWh of total power savings Northwest initiative that focusses on up to 2,000 degrees celsius destroys organic

Promoting low-carbon economy driven by implementation of IIoT, usage advanced use of Hydrogen and CO 2 and compounds while enabling safe recycling of

Carbon abatement study to reduce absolute carbon of LED lights and VFD conversion for HRT, Hydrogen storage inorganic compounds into clinker chemistry.

reduction and achieve net zero carbon HCT and slurry feed pump Installed efficient new boilers at the Implementation of co-processing technology

Energy management through energy audits, Undertaking IIoT implementation in Middlewich site producing the same makes it even more efficient by facilitating use of

improvement in operational efficiency and shift to other key areas steam output with 15% lower natural gas wastes as alternate fuels, which leads to reduction

consumption

renewable energy (Mambattu plant added solar Double effect evaporator in MUW3 in carbon emission. A Plastic feeding double

valve with a consumption capacity of 3 tonnes

power capacity) plant converted to quadruple effect Reduced carbon footprint at Lostock per day (TPD) of shredded plastic manually has

Initiating carbon capture and conversion to usable evaporator resulting into 14,976 MCal/hr site by replacing increased electricity been installed in the Mithapur Cement plant

generation from steam turbine with that

energy saving equivalent to 47,641 TPA

liquid form at TCE to produce carbon neutral CO 2 emission reduction from natural gas kiln which is enabling a 0.5 MT reduction in fuel

Sodium Bicarbonate consumption for every 1 MT of plastic processed.

UsA Integrated local counties sustainability

Achieved a total power reduction of agenda for all future projects (i.e.

450 kWh in C and D Boilers’ electrostatic renewable energy from hydropower

Minimising environment footprint precipitator (ESP) post implementing from the local weir, district heating from sustainability at Rallis

SBTi commitment findings of energy study, which indicated piping at the plant etc.), potentially

kickstarting the use of renewables

Conducted climate change risk assessment and waste mapping study potential to lower operating powers and Rallis is continuously working to improve its

comply with the boilers’ environmental long-term sustainability. It is implementing

Promoting smart agriculture

limits in its current Title V permit programmes and processes to improve its

Emphasis on continuous improvement in the recycle of water and waste environmental performance. In FY 2020-21,

materials Creating sustainable societies its total absolute emission was 69.26 million

Transitioning to clean fuels and technology and higher use of alternate Extensive tree planation drive across 500 acres tonnes CO e, fresh water withdrawal was 329.59

2

materials (i.e. plastic waste for cement) (target of 3 million tree plantation by 2030) megalitres, treated water discharged was 72.13

Continuous performance monitoring with air emissions monitoring systems ‘Prakriti’ Mitra-Sakhi Mandals megaliters and energy utilisation from renewable

and pilot concentrator Promoting species conservation and strengthening (solar) source was 3,464 Mwh.

Responsible Care and CORE certified operations (India) biodiversity: restoration and conservation of coral For more information, you can refer to pages

reefs (2,000 m area coverage)

2

34-35 of Rallis' Annual Report 2020-21.

46 47