Page 82 - Tata_Chemicals_yearly-reports-2019-20

P. 82

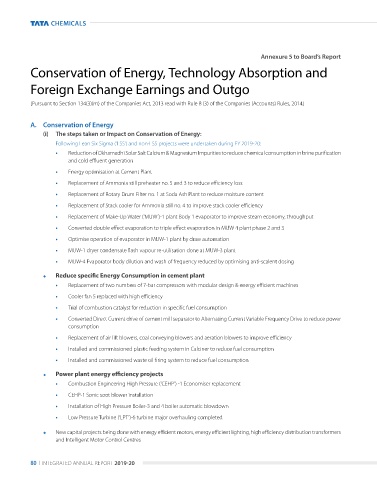

Annexure 5 to Board’s Report

Conservation of Energy, Technology Absorption and

Foreign Exchange Earnings and Outgo

[pursuant to Section 134(3)(m) of the Companies act, 2013 read with rule 8 (3) of the Companies (accounts) rules, 2014]

A. Conservation of Energy

(i) The steps taken or Impact on Conservation of Energy:

Following lean Six Sigma (‘lSS’) and non-lSS projects were undertaken during FY 2019-20:

• reduction of okhamadhi Solar Salt Calcium & Magnesium Impurities to reduce chemical consumption in brine purification

and cold effluent generation

• energy optimisation at Cement plant

• replacement of ammonia still preheater no. 5 and 3 to reduce efficiency loss

• replacement of rotary drum Filter no. 1 at Soda ash plant to reduce moisture content

• replacement of Stack cooler for ammonia still no. 4 to improve stack cooler efficiency

• replacement of Make-up Water (‘MuW’)-1 plant Body 1 evaporator to improve steam economy, throughput

• Converted double effect evaporation to triple effect evaporation in MuW 4 plant phase 2 and 3

• optimise operation of evaporator in MuW-1 plant by draw automation

• MuW-1 dryer condensate flash vapour re-utilisation done at MuW-3 plant

• MuW-4 evaporator body dilution and wash of frequency reduced by optimising anti-scalent dosing

u Reduce specific Energy Consumption in cement plant

• replacement of two numbers of 7-bar compressors with modular design & energy efficient machines

• Cooler fan 5 replaced with high efficiency

• trial of combustion catalyst for reduction in specific fuel consumption

• Converted direct Current drive of cement mill separator to alternating Current Variable Frequency drive to reduce power

consumption

• replacement of air lift blowers, coal conveying blowers and aeration blowers to improve efficiency

• Installed and commissioned plastic feeding system in Calciner to reduce fuel consumption

• Installed and commissioned waste oil firing system to reduce fuel consumption

u Power plant energy efficiency projects

• Combustion engineering High pressure (‘CeHp’) -1 economiser replacement

• CeHp-1 Sonic soot blower installation

• Installation of High pressure Boiler-3 and 4 boiler automatic blowdown

• low pressure turbine (‘lpt’)-6 turbine major overhauling completed

u new capital projects being done with energy efficient motors, energy efficient lighting, high efficiency distribution transformers

and Intelligent Motor Control Centres

80 I Integrated annual report 2019-20