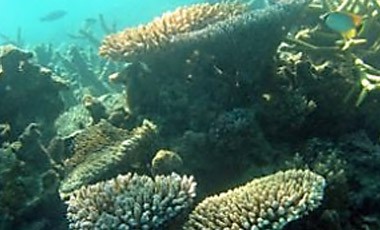

North America

At Tata Chemicals North America, sustainability is woven into the very fabric of its operations. Across geographies, the company drives initiatives for conservation of energy and water, restriction of emissions and better management of waste.

Energy

Energy

Energy is a significant material aspect for Tata Chemicals North America (TCNA).

Along with fossil fuels, TCNA uses grid power as an additional source of energy. To manage the downstream energy consumption, TCL dispatches more than 90 per cent volume of its total products through rail transport.

Emissions

Emissions

Emissions are critical to the organisation as they have impact on climate change and air quality. Emission-related goals are measured against Balance Score Card and Responsible Manufacturing Index. Over the years, TCL has introduced internal norms to provide a safer and better environment for the surrounding communities. Furthermore, all environmental regulations are being adhered to, and in-house monitoring is done on a daily basis. The organisation measures emissions from the combustion processes using continuous emission and opacity monitors. These measures are reported to the US EPA, IMA/NA, CDP and GRI-G4 reporting.

Combustion of natural gas and coal for electrical and steam generation results in NOx and SOx emissions. Tata Chemicals North America operations processes do not consume or generate ozone depleting substances (ODS).

Fugitive emissions are controlled by bag-houses and scrubbers with no impact on the environment. Recent installation of low NOx burners has resulted in a remarkable reduction in NOx emissions.

Water

Water

Water being a significant natural resource, is an important issue for Tata Chemicals. All measures to reduce water usage are implemented and water sources are metered and monitored regularly. The organisation has set forth stringent targets year-on-year to reduce water consumption which is reviewed periodically.

At TCNA, initiatives to reduce water consumption are underway – more than 80 per cent of the water that previously was lost to the evaporation ponds as part of tailings disposal is now recovered.

Waste

Waste

Tata Chemicals focuses on effective integration with the basic philosophy of resource optimisation, use of alternative sources and maximisation of “recycle and reuse” by innovation. Waste is a significant material aspect as it tends to degrade the environment if not managed suitably. Waste-related goals are taken in Balance Score Card and Responsible Manufacturing Index.

Hazardous and non-hazardous waste

Minimising the amount of waste produced is the key objective of Tata Chemicals, from both an economic and environmental perspective. We have implemented on-site segregation of waste at all the sites.

Primary recycled material at TCNA is decahydrate crystal configuration of soda ash that develops in the holding ponds. This material is mechanically harvested and returned to the process to supplement the production output. Any soda ash spillage in the product load out area is collected using vacuum trucks and returned to the production process for recycling thereby minimising water wastage.