Page 49 - Tata_Chemicals_yearly-reports-2017-18

P. 49

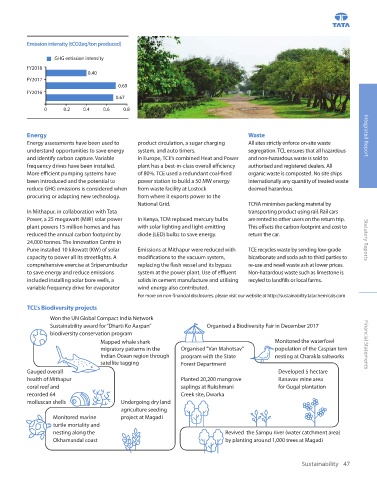

Emission intensity (tCO2eq/ton produced)

Energy Waste Integrated Report

Energy assessments have been used to product circulation, a sugar charging All sites strictly enforce on-site waste

understand opportunities to save energy system, and auto timers. segregation. TCL ensures that all hazardous

and identify carbon capture. Variable In Europe, TCE’s combined Heat and Power and non-hazardous waste is sold to

frequency drives have been installed. plant has a best-in-class overall e ciency authorised and registered dealers. All

More e cient pumping systems have of 80%. TCE used a redundant coal- red organic waste is composted. No site ships

been introduced and the potential to power station to build a 50 MW energy internationally any quantity of treated waste

reduce GHG emissions is considered when from waste facility at Lostock deemed hazardous.

procuring or adapting new technology. from where it exports power to the

National Grid. TCNA minimises packing material by

In Mithapur, in collaboration with Tata transporting product using rail. Rail cars

Power, a 25 megawatt (MW) solar power In Kenya, TCM replaced mercury bulbs are rented to other users on the return trip.

plant powers 15 million homes and has with solar lighting and light-emitting This o sets the carbon footprint and cost to

reduced the annual carbon footprint by diode (LED) bulbs to save energy. return the car.

24,000 tonnes. The Innovation Centre in Statutory Reports

Pune installed 10 kilowatt (KW) of solar Emissions at Mithapur were reduced with TCE recycles waste by sending low-grade

capacity to power all its streetlights. A modi cations to the vacuum system, bicarbonate and soda ash to third parties to

comprehensive exercise at Sriperumbudur replacing the ash vessel and its bypass re-use and resell waste ash at lower prices.

to save energy and reduce emissions system at the power plant. Use of e uent Non-hazardous waste such as limestone is

included installing solar bore wells, a solids in cement manufacture and utilising recyled to land lls or local farms.

variable frequency drive for evaporator wind energy also contributed.

For more on non- nancial disclosures, please visit our website at http://sustainability.tatachemicals.com

TCL's Biodiversity projects

Won the UN Global Compact India Network

Sustainability award for “Dharti Ko Aarpan” Organised a Biodiversity Fair in December 2017

biodiversity conservation program

Mapped whale shark Monitored the waterfowl

migratory patterns in the Organised “Van Mahotsav” population of the Caspian tern Financial Statements

Indian Ocean region through program with the State nesting at Charakla saltworks

satellite tagging Forest Department

Gauged overall Developed 5 hectare

health of Mithapur Planted 20,200 mangrove Ranavav mine area

coral reef and saplings at Rukshmani for Gugal plantation

recorded 64 Creek site, Dwarka

molluscan shells Undergoing dry land

agriculture seeding

Monitored marine project at Magadi

turtle mortality and

nesting along the Revived the Sampu river (water catchment area)

Okhamandal coast by planting around 1,000 trees at Magadi

Sustainability 47