Page 129 - Tata_Chemicals_yearly-reports-2017-18

P. 129

(iv) Water Purifier – Tata Swach: Safe drinking water is a 4. Has the Company taken any steps to procure goods

basic human need and its non-availability has been and services from local and small producers, including

a major concern worldwide. The vision for Tata Swach communities surrounding their place of work? If yes,

is to reduce the incidence of water borne diseases by what steps have been taken to improve the capacity and

making safe drinking water accessible to all. Tata Swach capability of local and small vendors?

is an offline household water purification system which Yes, the Company has a vendor development program. Over the

purifies water without electricity or running water. This years, the Company has promoted local contractors and service

year Tata Swach launched a new filter cartridge that providers and provides them opportunities. Additionally, the

provided upto 6000 litres of clean drinking water. Company has also promoted skills and livelihood development

2. For each such product, provide the following details in in the neighbouring community through various training and

respect of resource use (energy, water, raw material, etc.) community development programs. The Company has also

per unit of product (optional): established an apprentice training center to improve capacity.

The Company also keeps exploring development of suppliers

i. Reduction during sourcing/production/distribution from socially and economically backward communities under

achieved since the previous year throughout the its Affirmative Action Program helping them with regulatory Integrated Report

value chain?

processes, technical training and other capacity building

We use solar energy for production of solar salt which efforts so that they can become registered vendors of the

is an input to our production process. At Mithapur, organisations. Many of these vendors are now also vendors of

we achieved 5.04% reduction in Specific Water other organisations besides TCL.

consumption. We also improved our water use in the

5. Does the Company have a mechanism to recycle products

Sriperumbudur facility by achieving 4.5% reduction in

and waste? If yes, what is the percentage of recycling of

Specific Water consumption during 2017-18 from the

products and waste? (Separately as <5%, 5-10%, >10%).

previous year.

Also, provide details thereof, in about 50 words or so.

ii. Reduction during usage by consumers (energy, The Company focuses on effective integration with the basic

water) has been achieved since the previous year?

philosophy of resource optimisation, use of alternative sources

Chemicals which we produce are intermediate products and maximisation of “recycle and reuse” by innovation.

for the customers to produce final products such as

Our cement plant at Mithapur is unique waste to wealth

glass, detergents, etc. The Company set target annually Statutory Reports

initiative. In 2017-18 we have replaced 84.04% of virgin

to improve energy efficiency, water consumption, waste

limestone with recycled material like limestone fines, fly ash,

management, etc. to produce intermediate products

effluent solids, etc. Our soda ash filtration system is the first of

for the customers.

its kind in the world and solids are filtered out of the wastewater

Water purifier consumes zero electricity which helps using Larox filters. Filtered solids i.e. Effluent Solids Filter (ESF)

customers in saving electricity at their end. Also, it does cake is utilized to make cement.

not make use of harmful chemicals.

Most of our hazardous waste (spent catalysts and used/waste

In Food segment, we ensure quality of the products in oil) is recyclable and sent to Ministry of Environment and

such a way that it acts as nutritional ingredient for the Forests (MoEF) approved recyclers. In collaboration with our

customers. chemical suppliers (Urefix-Urea toughening agent, cooling

3. Does the Company have procedures in place for tower chemicals), we have taken up an initiative to reuse

sustainable sourcing (including transportation)? If yes, empty plastic drums.

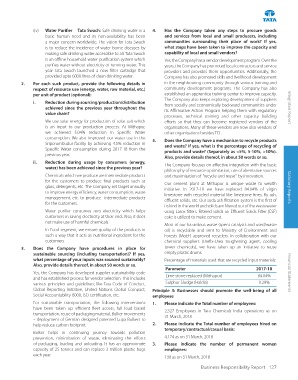

what percentage of your inputs was sourced sustainably? Percentage of materials used that are recycled input materials:

Also, provide details thereof, in about 50 words or so.

Parameter 2017-18

Yes, the Company has developed supplier sustainability code Financial Statements

Lime stone replaced (Mithapur) 84.04%

and has established process for vendor selection. This includes

various principles and guidelines; like Tata Code of Conduct, Sulphur Sludge (Haldia) 0.29%

Global Reporting Initiative, United Nations Global Compact, Principle 3: Businesses should promote the well-being of all

Social Accountability-8000, ISO certification, etc. employees

For sustainable transportation, the following interventions 1. Please indicate the Total number of employees:

have been taken up: efficient fleet access, full load based

2,327 Employees in Tata Chemicals India operations as on

transportation, reuse of packaging material, Bulker movements

31 March, 2018

– deployment of German designed patented Lupa Bulkers to

help reduce carbon footprint. 2. Please indicate the Total number of employees hired on

temporary/contractual/casual basis:

Bulker helps in continuing journey towards pollution

prevention, minimisation of waste, eliminating the efforts 4,174 as on 31 March, 2018

of packaging, loading and unloading. It has an approximate 3. Please indicate the number of permanent women

capacity of 25 tonnes and can replace 3 million plastic bags employees:

each year.

138 as on 31 March, 2018

Business Responsibility Report 127