Page 83 - Tata_Chemicals_yearly-reports-2020-2021

P. 83

Integrated Report Statutory Reports Financial Statements

1-59 Board's Report 147-300

• Optimisation of unloading time for Air • Reduction of water specific consumption by

Compressor: Minimised low load compressor implementing mechanical seal water recirculation

operations by diverting load to partially loaded system and installation of new filter plates

compressor and optimised total unloading • Reduction of acid specific consumption by

time which helped in reducing 10% of replacement of filter plates, installation of strainers

energy consumption of air compressors. Savings at different process lines and streamlining the

from modification of compressor system is 20,500 reaction process

units per month and ` 15 lakh annually

• Reduction in specific power consumption

• Optimisation of Air Handling Unit ('AHU') running

hours by Building Management System ('BMS'): by installation of capacitor banks, 6 Variable

By using BMS, running hours of AHU have been Frequency Drives (VFDs), 160 KVA Uninterrupted

optimised which helped in monthly savings Power Supply (UPS) and continuous monitoring

of 15,500 units. Annual savings would be of energy

` 10.88 lakh At the Innovation Centre, Pune:

• Reduction of Maximum Demand ('MD') from 3,000 • Installation of solar panels for street lights

KVA to 2,400 KVA: By reducing MD from 3,000 KVA resulting in a saving of 3,185.13 kWh

to 2,400 KVA helps in reducing MD fixed cost from

` 11.5 lakh per month to ` 9.2 lakh per month. (ii) The steps taken by the Company for utilising

It helped in reducing overall total per unit cost alternate sources of energy:

by ` 7.4 per unit to ` 7.0 per unit

• Use of alternate fuels at Mithapur:

In the Silica Plant at Cuddalore:

Ø Consumed 358 MT of shredded plastic in

• Reduction of sodium silicate specific consumption Cement kiln (supplied from TCSRD facility)

by modification of agitator blades, installation of

better pump seals and auto packing machine Ø Applied to Gujarat Pollution Control Board

and replacement of filter press skirt boards and (GPCB) for 31 types of alternate fuels and are

scrapper in receipt of 2 samples for trial

• Reduction of coal specific consumption by • Solar capacity increased from 1.15 MW to

installation of dip pipes at hot water tanks, 1.9 MW at Mambattu by installation of Floating

equaliser plate at spray dryer and strainers at Solar Pond-2 (760 KW). It has increased annual

different process lines and by automation of dryer solar generation capacity from 16.8 lakh units to

operation using PLC 28 lakh units

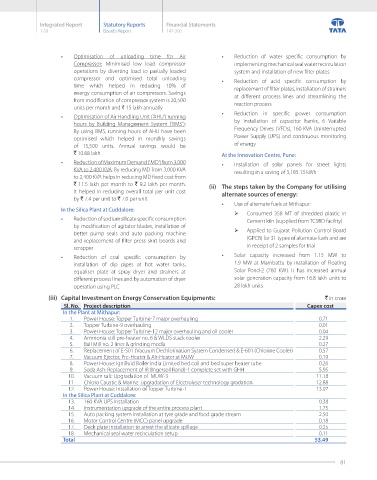

(iii) Capital Investment on Energy Conservation Equipments: ` in crore

Sl. No. Project description Capex cost

In the Plant at Mithapur:

1. Power House: Topper Turbine-7 major overhauling 0.71

2. Topper Turbine-9 overhauling 0.01

3. Power House: Topper Turbine-12 major overhauling and oil cooler 0.04

4. Ammonia still pre-heater no. 6 & WLDS stack cooler 2.29

5. Ball Mill no. 2 liner & grinding media 0.27

6. Replacement of E-501 (Vacuum Dechlorination System Condenser) & E-601 (Chlorine Cooler) 0.57

7. Vacuum Ejector, Pre-Heater & Air-Heater at MUW 0.19

8. Power House: Ignifluid Boiler India Limited bed coil and bed super heater tube 0.26

9. Soda Ash: Replacement of IR (Ingersoll Rand)-1 complete set with GHH 5.95

10. Vacuum salt: Upgradation of MUW-3 11.18

11. Chloro Caustic & Marine: upgradation of Electrolyser technology gradation 12.88

12. Power House: Installation of Topper Turbine-1 13.97

In the Silica Plant at Cuddalore:

13. 160 KVA UPS Installation 0.38

14. Instrumentation upgrade of the entire process plant 1.75

15. Auto packing system installation at tyre grade and food grade stream 2.50

16. Motor Control Centre (MCC) panel upgrade 0.18

17. Deck plate installation to arrest the silicate spillage 0.25

18. Mechanical seal water recirculation setup 0.11

Total 53.49

81