Page 41 - Tata_Chemicals_yearly-reports-2020-2021

P. 41

Integrated Report Statutory Reports Financial Statements

Integrated Annual Report 2020-21 Strengthening our People, 60-146 147-300

Assets and Environmental

Safety Practices

FY 2020-21 occupational health and safety (OHS) initiatives

Initiatives Impact Vulnerability Tracking safety

Progressive Safety Renewed focus on OHS Global implementation assessment through performance with

Index (PSI) performance through 60% baseline for the Indian Data Analytics Progressive Safety

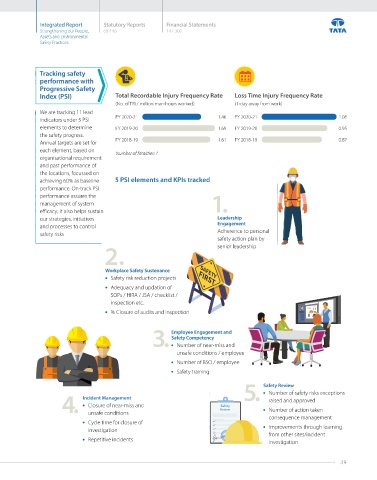

identified lead indicators operations Index (PSI) Total Recordable Injury Frequency Rate Loss Time Injury Frequency Rate

We have developed a (No. of TRI / million man-hours worked) (1-day away from work)

Data Analytics Platform We are tracking 11 lead

to gain organisation-wide indicators under 5 PSI FY 2020-21 1.46 FY 2020-21 1.08

safety insights for tracking elements to determine FY 2019-20 1.69 FY 2019-20 0.95

Focus on Employee Training and focussed 1.55 near-miss reported / various safety lead and lag the safety progress.

Engagement interventions employee with 86% indicators. The platform uses Annual targets are set for FY 2018-19 1.61 FY 2018-19 0.87

Cross-Functional Teams closure ( ) analytical tools like Natural each element, based on Number of fatalities: 1

(CFTs) for deploying 221 people trained in Language Processing (NLP) organisational requirement

safety initiatives process safety ( ) for generating word clouds and past performance of

and historic data analysis the locations, focussed on

Joint management- for forecasting vulnerable achieving 60% as baseline 5 PSI elements and KPIs tracked

workmen committees at areas and activities to performance. On-track PSI

sites to focus on OHS

avoid incidents. Real-time performance assures the

dashboards communicate management of system 1.

Operational Safety Long-term asset 89.90% - closure of audit results to the management. efficacy; it also helps sustain

(Safety Management management plan action points ( ) The platform also updates all our strategies, initiatives Leadership

System, Asset and structural safety 100% Indian operations data automatically from the Engagement

Integrity, Risk programmes and processes to control Adherence to personal

Assessment, Audit undergone BAA WSO portal for employees. safety risks safety action plan by

and Inspection) Internal / external audits, senior leadership

inspections, surprise checks

and expert engagement 2 .

Gap analysis and

implementation of Way forward Workplace Safety Sustenance

new safety process and Sustaining on-going Safety risk reduction projects

checklists (benchmarked safety improvement Adequacy and updation of

with Tata Health & Safety programmes SOPs / HIRA / JSA / checklist /

Management System & inspection etc.

ISO 45001) Standardisation and % Closure of audits and inspection

certification of health

Business Assurance Audit & safety systems

(BAA) for high-risk areas

Enhancing focus 3. Employee Engagement and

on lead indicators Safety Competency

Digitalisations and Implementation of Successful completion of through PSI Number of near-miss and

Data analytics safety analytics for pilot for safety wearables unsafe conditions / employee

global operations Audit and training module Strengthening Number of BSO / employee

of training and

Enhancing scope of and permit to work, certification modules Safety training

WSO (Work Safe Online) change management,

for digitalisation of medical modules under Enhancing the scope Safety Review

safety process design of digitalisation, IoT 5. Number of safety risks exceptions

and AI for safety Incident Management

IoT solutions for workers’ management 4. Closure of near-miss and raised and approved

health & safety unsafe conditions Review Number of action taken

consequence management

Cycle time for closure of

investigation Improvements through learning

( ) Increase (over past financial year) Repetitive incidents from other sites/incident

( ) Decrease (over past financial year) investigation

38 39