Page 77 - Tata_Chemicals_yearly-reports-2017-18

P. 77

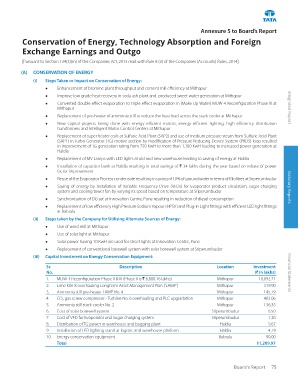

Annexure 5 to Board’s Report

&RQVHUYDWLRQ RI (QHUJ\ 7HFKQRORJ\ $EVRUSWLRQ DQG )RUHLJQ

Exchange Earnings and Outgo

[Pursuant to Section 134(3)(m) of the Companies Act, 2013 read with Rule 8 (3) of the Companies (Accounts) Rules, 2014]

(A) CONSERVATION OF ENERGY

(i) Steps Taken or Impact on Conservation of Energy:

ʀ Enhancement of bromine plant throughput and cement mill efficiency at Mithapur

ʀ Improve low grade heat recovery in soda ash plant and produced sweet water generation at Mithapur

ʀ Converted double effect evaporation to triple effect evaporation in (Make Up Water) MUW-4 Reconfiguration Phase III at

Mithapur Integrated Report

ʀ Replacement of pre-heater of ammonia still to reduce the heat load across the stack cooler at Mithapur

ʀ New capital projects being done with energy efficient motors, energy efficient lighting, high efficiency distribution

transformers and Intelligent Motor Control Centers at Mithapur

ʀ Replacement of super heater coils at Sulfuric Acid Plant (SAP2) and use of medium pressure steam from Sulfuric Acid Plant

(SAP1) in Turbo Generator (TG) motive section by modification of Pressure Reducing Device System (PRDS) loop resulted

in improvement of TG generation rating from 750 KwH to more than 1,100 KwH leading to increased power generation at

Haldia

ʀ Replacement of MV Lamps with LED lights at old and new warehouse leading to saving of energy at Haldia

ʀ Installation of capacitor bank at Haldia resulting in total savings of ` 34 lakhs during the year based on rebate of power

factor improvement

ʀ Reuse of the Evaporator Process condensate resulting in saving of 10% of ground water in terms of Kilolitres at Sriperumbudur

ʀ Saving of energy by installation of Variable Frequency Drive (VFDs) for Evaporator product circulation, sugar charging Statutory Reports

system and cooling tower fan by varying its speed based on temperature at Sriperumbudur

ʀ Synchronisation of DG set at Innovation Centre, Pune resulting in reduction of diesel consumption

ʀ Replacement of low efficiency High Pressure Sodium Vapour (HPSV) and Plug-in Light fittings with efficient LED light fittings

at Babrala

(ii) Steps taken by the Company for Utilising Alternate Sources of Energy:

ʀ Use of wind mill at Mithapur

ʀ Use of solar light at Mithapur

ʀ Solar power having 10 KwH are used for street lights at Innovation Centre, Pune

ʀ Replacement of conventional borewell system with solar borewell system at Sriperumbudur

(iii) Capital Investment on Energy Conservation Equipment:

Sr. Description Location Investment

No. (` In lakhs) Financial Statements

1. MUW-4 Reconfiguration Phase II & III (Phase II is ` 6,800.16 lakhs) Mithapur 10,092.71

2. Lime Kiln 8 overhauling Longterm Asset Management Plan (‘LAMP’) Mithapur 319.90

3. Ammonia still pre-heater LAMP No. 4 Mithapur 145.79

4. CO 2 gas screw compressor - Turbine No. 6 overhauling and PLC upgradation Mithapur 403.06

5. Ammonia still stack cooler No. 2 Mithapur 136.35

6. Cost of solar borewell system Sriperumbudur 6.50

7. Cost of VFD for Evaporator and Sugar charging system Sriperumbudur 1.20

8. Distribution of TG power in warehouse and bagging plant Haldia 9.67

9. Installation of LED lighting stand at logistic and warehouse platform Haldia 4.79

10. Energy conservation equipment Babrala 90.00

Total 11,209.97

Board's Report 75